Productique Québec’s mission is to improve productivity and drive innovation in businesses by promoting the acquisition of knowledge and expertise in digital technologies associated with manufacturing production.

Productique Québec’s expertise include Digital Product Lifecycle Management.

Médias

Secteurs d'activités

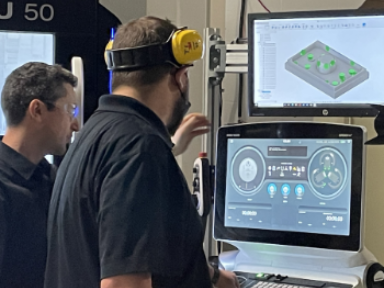

- Assistance in the acquisition and / or implementation of CNC equipment

- Assistance in the acquisition and / or implementation of product configurators (E-commerce)

- Assistance in the acquisition and / or implementation of software (ERP, MES, CRM, CAD, CAM, PDM, PLM, etc.)

- Bridge creation to transfer data between computer-aided design and integrated management systems (CAD-ERP)

- Business process reengineering

- Creation and implementation of a digital plan in the audit / diagnosis of digital technologies (Industry 4.0)

- Creation of utilities and / or automation to reduce repetitive tasks in computer-aided design and manufacturing (CAD / CAM)

- Development of corporate training programs

- Development of data acquisition and processing systems of CNC machines.

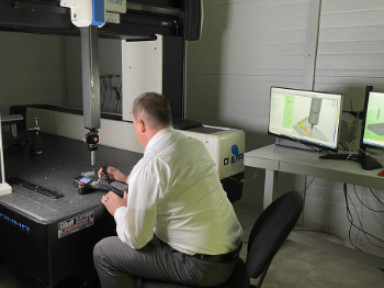

- Digital Product Lifecycle Management

- Modeling dashboards (BI)

Digital management of the life-cycle of manufactured products

- CAD software (SolidWorks, SolidEdge, Autodesk Inventor, Fusion 360, Onshape, etc.)

- CAM software (Vericut, Mastercam)

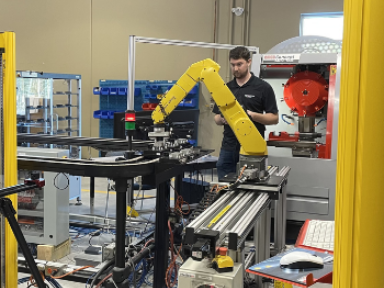

Technology showcase demonstrating the 4.0 industrial ecosystem in action

- Automata (Allen Bradley and Omron)

- Collaborative robot (Universal robot)

- Conveyor and automated warehouse

- Digital vision sensors, barcode readers, etc.

- Industrial robots (ABB and Fanuc)

- Industrial security (virtual curtains, zone scanner)

- Laser cutting

- Milling machine and CNC lathe

- 720, rue Longpré, Sherbrooke, J1G 4L3

- 819 822-8998

- Sébastien Houle

- General Manager

- 819 822-8998, ext. 1500

- sebastien.houle@productique.quebec