Inovem, an innovation center dedicated to wood and related materials, is a Collegial Centre for Technology Transfer (CCTT) integrated into the Cégep de Victoriaville. The center's mission is to stimulate innovation and development within companies operating in the second and third wood transformation sectors. Inovem serves a highly diversified sector that includes furniture manufacturers, wood component producers, architectural woodworking, kitchen cabinet makers, doors and windows manufacturers, office furniture producers, prefab housing, coffin makers, pallets, formwork, garden furniture, wooden crates, musical instruments, and appearance wood products.

Inovem supports companies in order to grow their efficiency and improve their performance. The Centre assists industries in adopting eco-responsible and greener practices; it promotes circular economy concepts in its actions with partners.

To fulfill its mission, Inovem relies on a multidisciplinary team of experts and a research infrastructure that includes industrial equipment and a state-of-the-art technology laboratory. Its offices are located at École nationale du meuble et de l’ébénisterie de Victoriaville.

The Centre d’innovation en ébénisterie et meuble has nearly 40 years of experience in applied research, technical assistance and business training. Invoem offers a practical and efficient support service, on a human scale, provided by professionals in the domain.

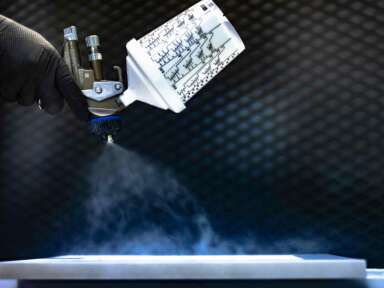

Its expertise is grouped into five main business areas: materials and resources of the future, finishing and durable finishing processes, productivity 4.0, digital design technologies and customer experience, and online sales technologies.

Inovem has 3 laboratories: mechanical and climatic tests, unique industrial finishes and the Laboratoire Desjardins des réalités mixtes.

Médias

- Analysis of the effect of microwaves during the drying of finishing products

- Application of powder paint on solid wood products

- Characterization and performance tests of materials and products

- Development and manufacture of prototypes of wooden products (chiller for cellar, wooden glasses)

- Factory layout and implementation of value-added manufacturing method for a door and window manufacturer

- Identification of equipment needs and support for the conversion of finishing processes based on water, UV and other products with low environmental impact

- Integration of specialized CAD software to facilitate the production process

- Robotic application and drying of UV curing finishing products

- Technical assistance in choosing materials and hardware for the manufacture of furniture (retractable bed)

- Use of virtual and augmented reality for product design, sales support and online sales

- Accelerated aging chamber

- Characterization and performance

- Conditioning chamber (temperature and pressure)

- Equipment for wood welding by dowel

- Finishing workshop

- Gas infrared radiation drying chamber

- Linear and circular friction wood welding equipment

- Mechanical test universal machine (tension, elongation, bending, compression)

- Robot for application and drying of finishing by UV cross-linking and UV LED

- Testing equipment (gloss, roughness, color, hardness, adhesion, friction)

- Two application booths for aqueous and powdered finishes

- Two baking tunnels for powder finishing products (gas and electric infrared)

- Ultraviolet radiation drying conveyor

- Universal drying laboratory (hit air, microwave and infrared)

- Welding laboratory

- 765, rue Notre-Dame Est, Victoriaville, G6P 4B2

- 819 758-8219

- Bernard Lefrançois

- Manager

- 819 758-6401, ext. 2603

- lefrancois.bernard@cegepvicto.ca